Sometimes power is revealed within the smallest of details. Our friend Keith Jones at Total Seal shared a situation that one of his customers, Jeff Baldwin at Baldwin Racing Engines in Friedheim, Missouri faced recently. A small-block Chevy circle-track engine was in for its annual freshening after a season of races. After it was reassembled and run on the dyno, the engine was down a significant chunk of torque and horsepower. It took several days of checking to find the culprit — ring grooves.

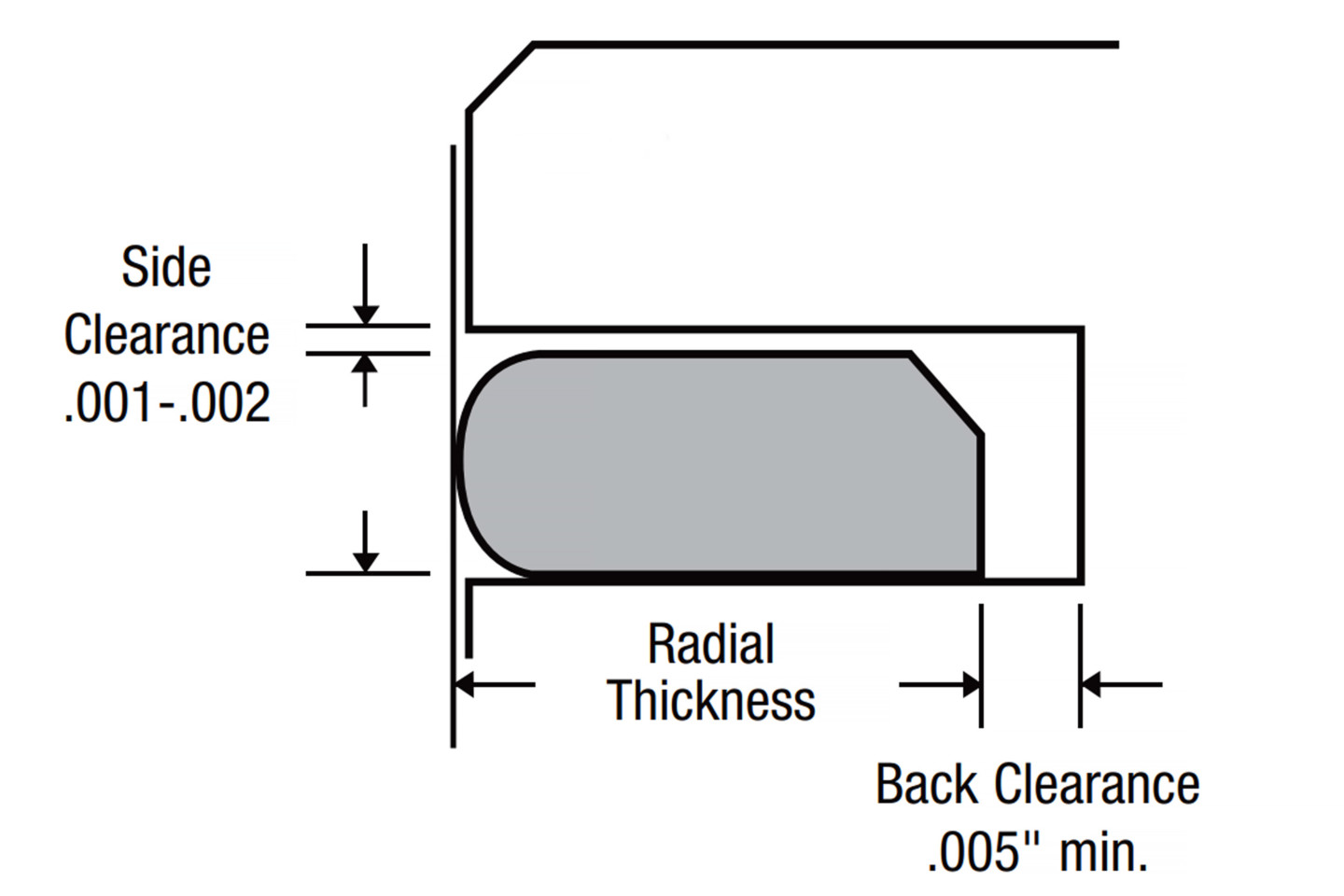

Careful measurement of the top ring grooves on all eight pistons revealed abnormal wear on the lower portion of the top ring land. This increased the vertical clearance for the top ring. The typical spec is to hold this clearance to 0.0012 to 0.0020 inch as closely as possible. These particular pistons exhibited excessive wear on the bottom side of the top ring grooves, which tapered out toward the outside of the piston. Out at the edges, the clearance grew to over 0.0030 inch on a couple of the pistons. According to Jones, this makes it very difficult for combustion pressure to help seal the ring to the cylinder wall.

This illustration reveals the spec of between 0.001 and 0.002-inch for what is often called ring side clearance. If the clearance is too tight, it does not allow sufficient room for cylinder pressure to enter behind the ring and push it out to help seal. If the clearance is too large, pressure can escape and not do its job.

The remedy was to bore the cylinders out to the next size and hone it to be able to add new pistons and rings with the proper clearance. A subsequent dyno test brought the power back to where it was with the previous year’s baseline. The test revealed a 50 lb-ft of torque and 52 horsepower return of lost power. Keep in mind that this was not a gain of power but rather a return to where the engine had been running before the ring grooves wore out.

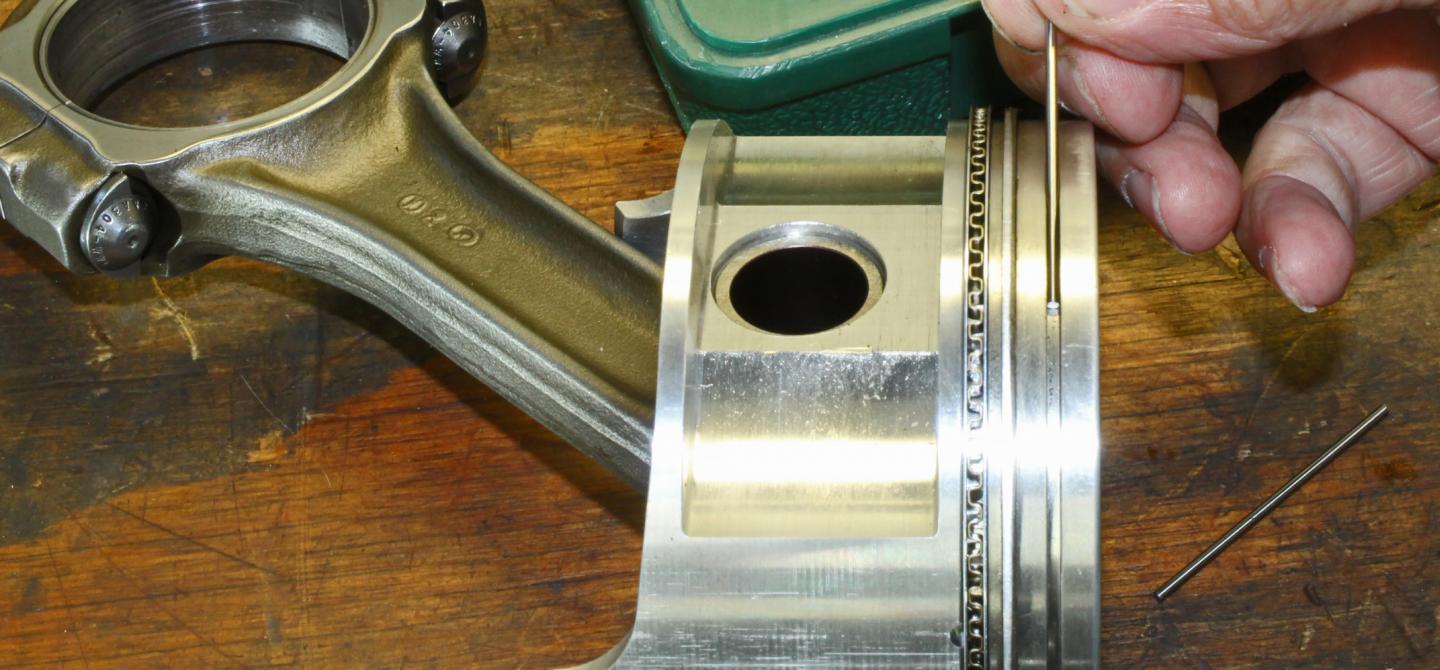

Our friends at Total Seal recommend using a pin gauge to accurately measure the top ring land to ensure that the vertical clearance is maintained as close to the minimum spec as possible. Pin gauges are easily found online and generally can be found in standard sizes in 0.001-inch increments. Look for pin gauges with a XX rating. This is the tightest range of variation on pin gauges for the best accuracy. It’s also a good idea to verify the pin gauge diameter with a micrometer. The gauges are also available in metric sizes for those working with metric ring packages.

Precise use of a set of pin gauges can identify worn pistons that will not do a good job of helping the rings seal the cylinder pressure. Trying to measure the actual clearance with the ring in place using a feeler gauge is too imprecise.