If you talk to ten engine builders, you may likely hear eight different procedures for cleaning cylinder walls right before engine assembly. Many engine builders hold serious opinions and believe that their way is the only way to clean a cylinder wall. We’re not here to argue or refute any of that. It’s entirely possible that all of these procedures will work. We have our own, but we decided first to talk to someone who works with piston rings on a daily basis.

We spoke with Keith Jones at Total Seal to ask him about his procedures. “I like something that is high-detergent, like automatic trans fluid (ATF) or similar right after honing. That helps to really pull the fine junk out of the crosshatch. I then use hot water and Dawn dish soap (high surfactant). Then I use a clear solvent like lacquer thinner with a lint-free towel or rag. I use lacquer thinner for the final step because it flashes off fast and I can see if there is any dirt still on the towel.”

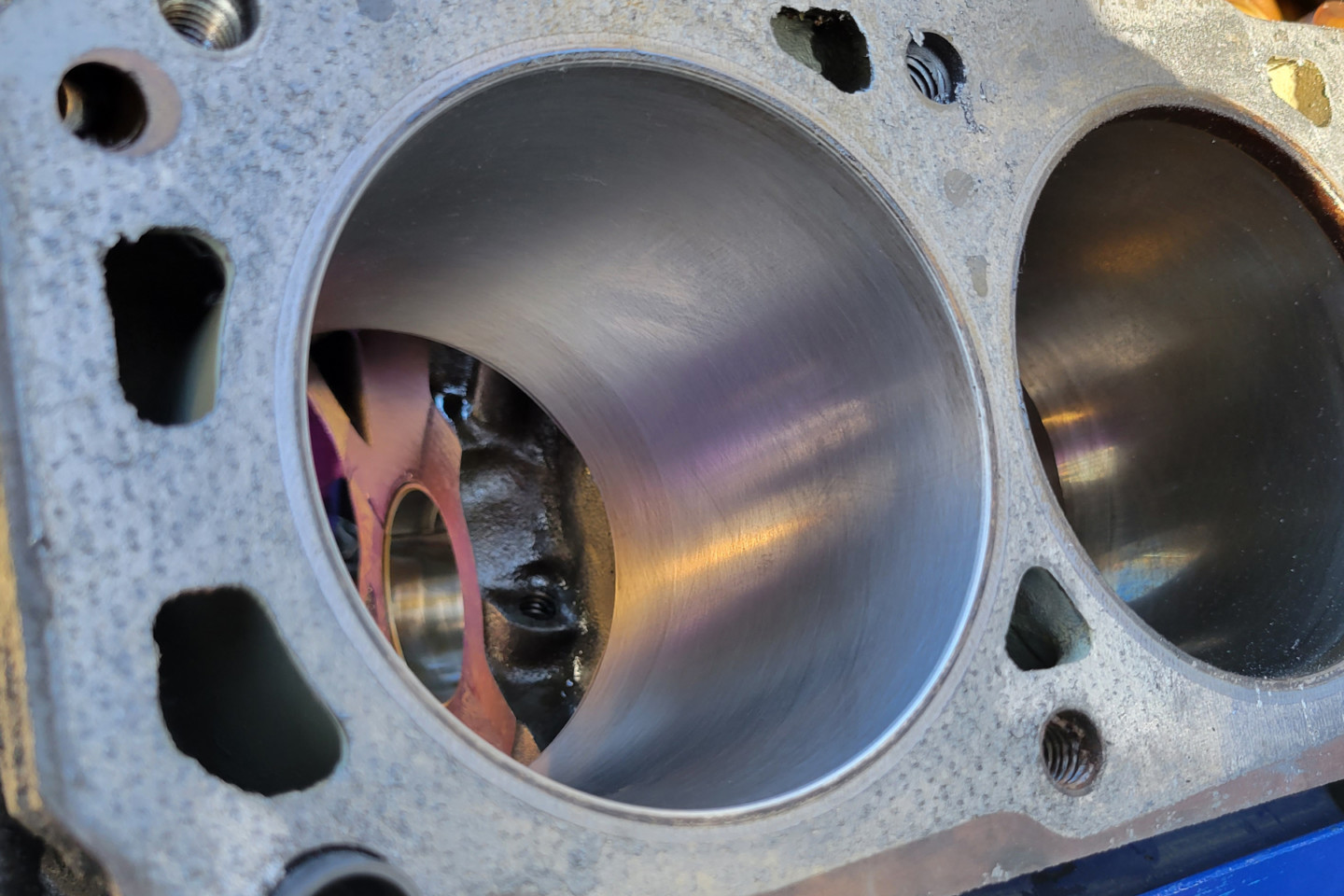

Our system is similar but in a different sequence that (of course) we think also works well. although we’re basing our opinion on evaluating this technique on the lack of grey grit on a clean white paper towel. With the cylinder block back on our engine stand fresh from the machine shop, we start by cleaning the entire block with hot water and laundry detergent. After a solid rinse with fresh water, we dry the block quickly with compressed air. Next, our efforts with lacquer thinner reveal that it leaves grit behind but it’s possible that we didn’t run enough sessions with the lacquer thinner to remove all the grit.

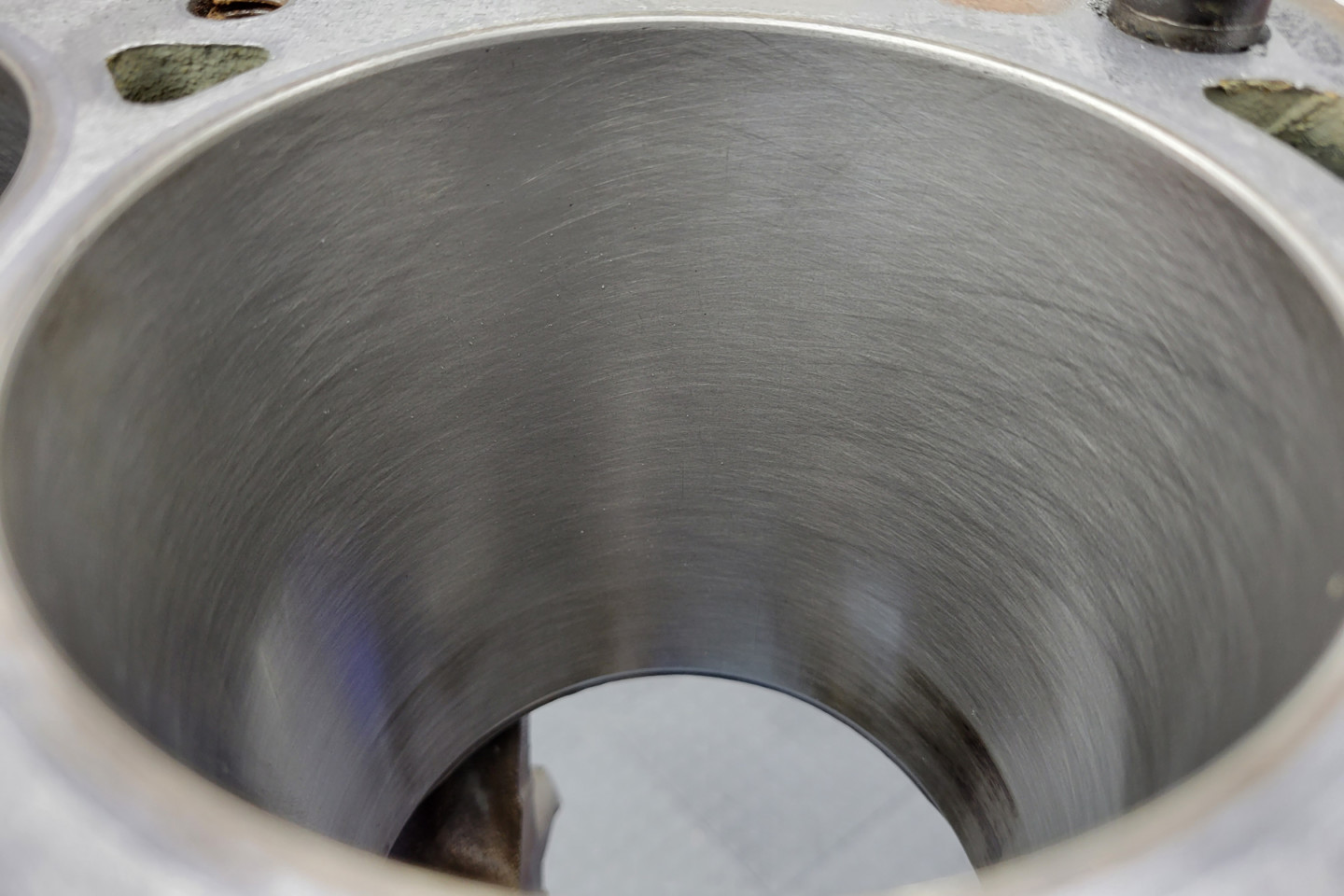

We generally have to clean each cylinder with a new white paper towel coated with Marvel Mystery Oil between four and six times before the white paper towel only shows the red of the oil instead of dark grey from the honing process. Keep cleaning until the paper towel no longer shows dirt.

After a suggestion from a friend who is a very meticulous engine builder/racer we decided to try Marvel Mystery oil. We place Marvel Mystery oil on a clean white paper towel to perform the final cleaning. We’ve found it takes between four and six rounds each time with a clean towel to finally remove all the honing grit from each cylinder. This process is a bit tedious but it’s the best way we’ve found to pull all the grit from the cylinder walls. We know the wall is clean when the final session results in no more grey grit results on our white paper towel so all you see are the red Marvel Mystery Oil stains.

Total Seal offers a dry cylinder wall coating called Quick Seat to help with the break-in process. Jones tells us, “For using Quick Seat we spray the cylinder with WD-40 then remove the excess. It is there to act as a bonding agent for the dry film to cling to the bore so it doesn’t need much. I spray the cylinders then wipe them down with the same lint-free blue towel roll I use to clean the cylinders. Then I lightly apply the Quick Seat.”

He also mentioned that if you don’t use the Quick Seat, a light coating of motor oil will suffice for initial lubrication on the cylinder wall for the first start of the engine. All of this is pretty simple, but it all comes down to ensuring the cylinder walls are clean.