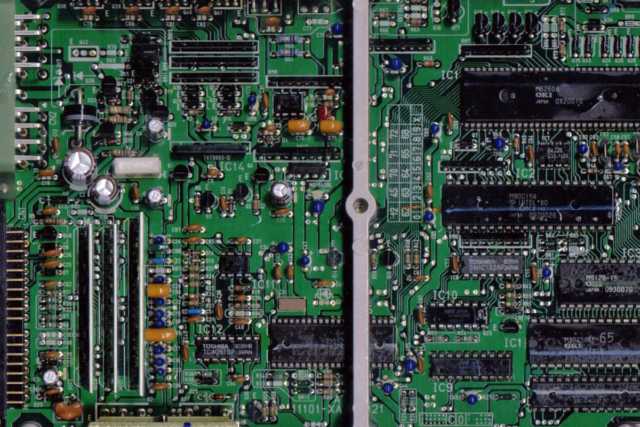

Production cars with engine control units (ECU) first started to appear around the beginning of the 1980s, and were intended to improve the efficiency of the engine in an effort to reduce emissions and increase fuel economy. These initial ECUs were a far cry from what we have today, they were very simple systems that processed inputs in analog and used a digital read only memory (ROM) chip to hold look-up tables and predetermined static values.

The units found in every production car and just about every aftermarket engine management system available today, are controlled using powerful microprocessors that are able to dynamically control every aspect of engine operation such as ignition timing, fueling, airflow, valve timing, etc.

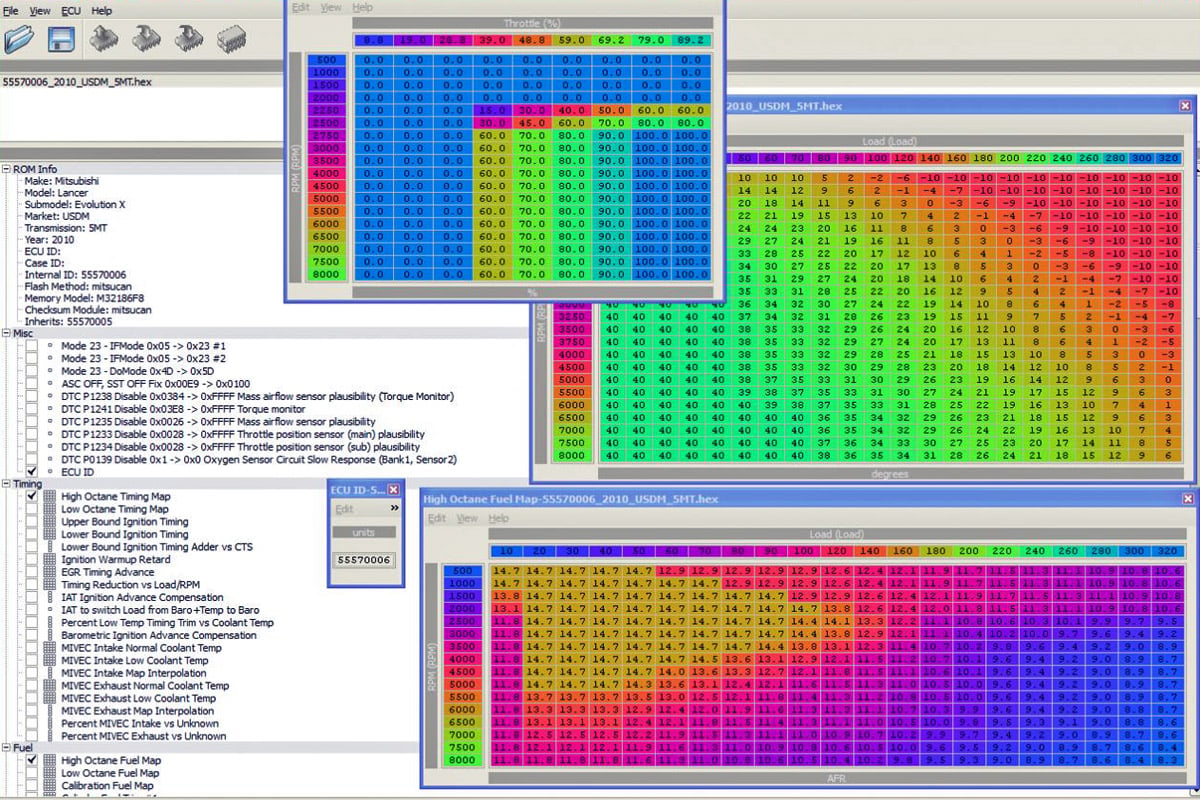

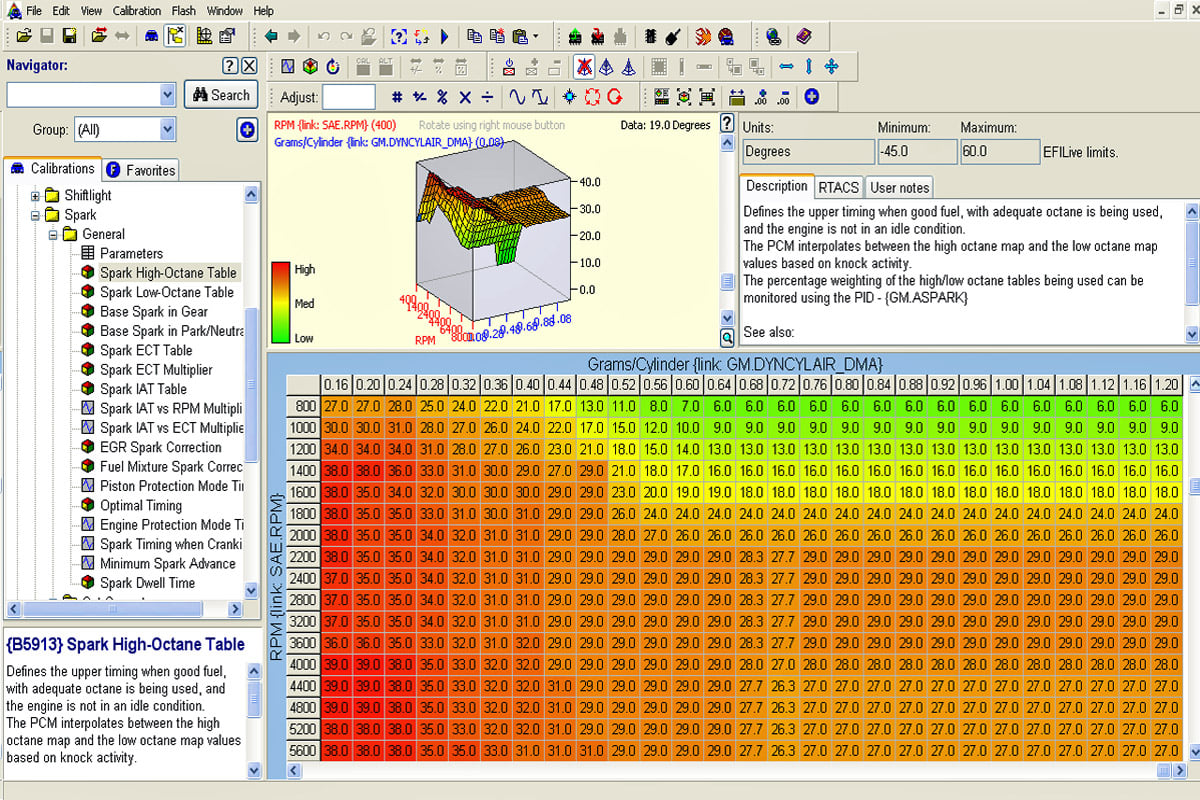

As the automotive industry continued its immersion into the tech sector, aftermarket manufacturers turned to the help of talented software engineers to reverse engineer some of these powerful controllers. They built software and hardware capable of disassembling and reading the raw hexadecimal code and converting it into a binary file, that displays high resolution 2D and 3D maps that could be recalibrated and rewritten to the ECU by tuning shops and race teams.

Steve Dinan of the iconic BMW tuning shop Dinan was truly a pioneer in the field of ECU tuning, cracking into the more primitive control units as early as 1982 and never looking back. In the video above from the guys over at /Drive, Dinan takes us deep into the world of ECUs and tuning.

The Basics Of The Modern Advantage

Every part of your engine’s valvetrain assembly and bottom end is only able to achieve maximum efficiency at one engine speed. Back in the day when carburetors were all we had, engine modifications would be “tuned” by carb jetting and distributor adjustments for peak torque and efficiency in a very small RPM window, which meant that any engine speed outside of this window would be off.

With the introduction of the first generation of ECUs, we were given the ability to adjust fueling and ignition timing maps for optimal efficiency at different combinations of engine speed and load. This may not have improved peak output over a carbureted engine – but low end torque, top end power, and throttle response were all improved.

The engine control units found in today’s modern vehicles and offered by aftermarket engine management companies take ECU tuning to another level. In addition to the ignition timing and fueling adjustments that were offered before, the ability to calibrate components like variable valve timing, variable valve lift, electronic boost control, volumetric efficiency tuning, MAF scaling, etc., were introduced.

This technological gift was able to take that single peak torque RPM window and widen it to a 3,000 to 4,000 RPM window; and if you add forced induction, this window can increase even further.

Left: An example of the open source tuning software ECUFlash. Right: An example of the tuning software EFILive.

/Drive’s video is definitely worth watching; it gives us a rare look into the engineering side of ECU tuning and engine calibration, covering topics such as the relationship between modern engine management systems and tuning for forced induction, fuel octane, variable valve timing, variable valve lift, ignition timing, etc.

Dinan even touches on the tuning war between race teams, where netting even an extra hundredth of a second by tweaking ECU calibrations might mean the difference between first place and losing.