Dry type oiling systems like those produced by ARE, are a viable option for heads-up racing and exotic motorsports applications, although they are clouded in a bit of mystery. This advanced oiling system provides countless amounts of benefits once the wet style oil pump is removed from the crankcase, and an external dry sump pump takes up the duty.

Dry type oiling systems like those produced by ARE, are a viable option for heads-up racing and exotic motorsports applications, although they are clouded in a bit of mystery. This advanced oiling system provides countless amounts of benefits once the wet style oil pump is removed from the crankcase, and an external dry sump pump takes up the duty.

For example, a wet sump system pulls oil through a pickup tube to supply the pump itself. During heavy acceleration and cornering, this design is prone to draw in cavitated oil which can starve the bearings and other key engine components. A dry sump design utilizes a separate tank that features internal baffles for an uninhibited oil supply. The engine will also lose viscous drag (oil resistance due to sloshing into rotating assembly) causing an increase in horsepower.

The pump itself is required to have two different stages. One that pressurizes the oil that resides in the separate holding tank that supplies the engine, and one that scavenges the oil that has made its way to the pan and returns it to the holding tank. This scavenging effect also removes excess air from the crankcase and keeps the pan mainly dry, hence the name “dry sump.”

“In a wet sump application, the oil pump is automatically driven by the camshaft or something that is predesigned by the engine manufacturer,” says Gary Armstrong of ARE. “When you go dry sump that internal pump goes away, it’s out of there, or in a garbage can, this particular pulley is what takes over for the external pump.”

ARE has a massive amount of real-world racing experience and has developed a new pump drive system, which allows you to convert a wide-range of engines over to this advanced oiling system. Allowing anyone to squeeze all the potential out of their street or track-goer.

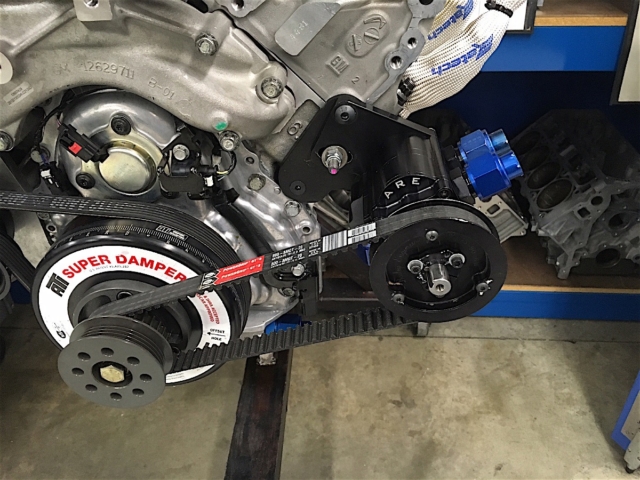

Thanks to the latest set of drive components from ARE you can lay claim to these gains without sacrificing your accessory drive components. While every dry sump pump they make is powered by a Gilmer or HTD timing belt driven by the crankshaft balancer, these new mandrels allow for additional drive gears.

Thanks to the latest set of drive components from ARE you can lay claim to these gains without sacrificing your accessory drive components. While every dry sump pump they make is powered by a Gilmer or HTD timing belt driven by the crankshaft balancer, these new mandrels allow for additional drive gears.

ARE has a wide-range of oiling systems, check out this killer dry sump setup on a Subaru Boxer engine.

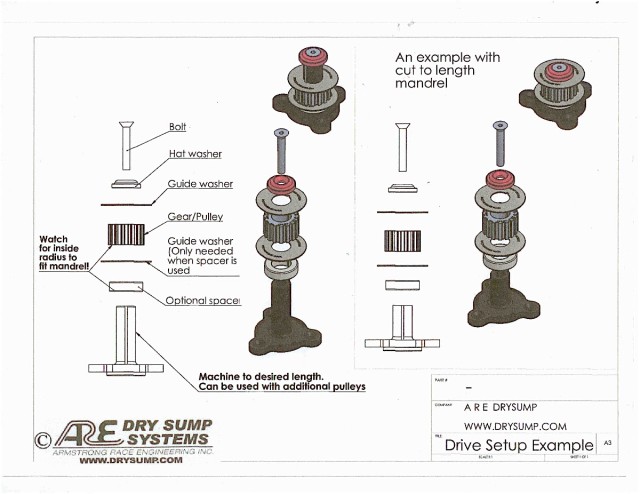

These new CNC turned three-bolt mandrels are designed to fit most aftermarket balancer designs, such as your typical ATI dampers. They also feature a one-inch diameter shaft that can accept a full range of gears to accommodate your particular accessory drive setup, and can be cut to length for clearance purposes. In this assembly a set of guide washers helps maintain belt and pulley alinement and are topped off by a hat washer and bolt.

“Not only will this design drive the dry sump pump, it is also able to power a customer’s alternator and water pump, among other things,” explains Armstrong. “This kind of added versatility is where this longer length pulley design shines.”

To find a dry sump system for you next project make sure to check out ARE‘s wide range of oiling systems.