It was a tale of two tables at the Manley Performance Products booth. Stage Right was Gary Mecklenburg manning the domestic table. On the opposite side, Stage Left, Tom Razzano was surrounded by sport compact gear. The debate at hand? Which camp had the most innovative new bottom end and valvetrain products for their respective markets. Who could make the best case? Who would rule the stump like Donald Trump? … roll tape.

It was a tale of two tables at the Manley Performance Products booth. Stage Right was Gary Mecklenburg manning the domestic table. On the opposite side, Stage Left, Tom Razzano was surrounded by sport compact gear. The debate at hand? Which camp had the most innovative new bottom end and valvetrain products for their respective markets. Who could make the best case? Who would rule the stump like Donald Trump? … roll tape.

Gary Mecklenburg, Domestic Applications

Mecklenburg is smooth, kick-back Southern Californian who is Manley’s regional sales manager on the left coast. More than a silver-tongued beach bum, Mecklenburg brings the calculating mind of a mechanical engineering degree from the University of California at Irvine to the party.

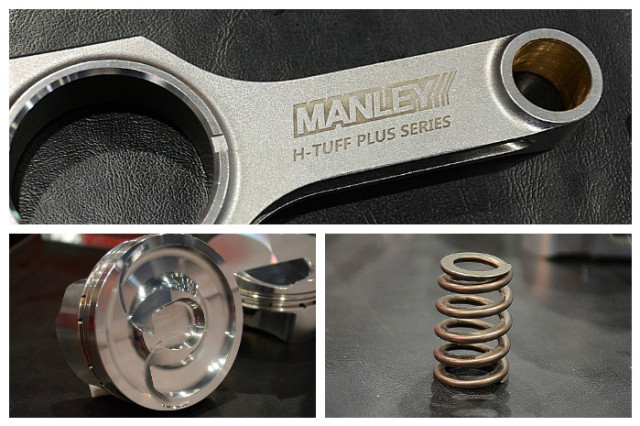

“We are reintroducing 351 gear for Windsor and Cleveland blocks. Pistons rods, cranks … but unlike the products from 20 years ago they are using current technology, 2618 material, ultra true ring lands, and modern machining. Our connecting rods are inexpensive, but take 900 horsepower.”

“We are reintroducing 351 gear for Windsor and Cleveland blocks. Pistons rods, cranks … but unlike the products from 20 years ago they are using current technology, 2618 material, ultra true ring lands, and modern machining. Our connecting rods are inexpensive, but take 900 horsepower.”

“Staying with Ford products and moving to the modular Ford gear. One of our highlights this year are our Coyote springs. They are capable of high lift, .600 lift, which is a good amount of lift and useful in many racing applications.”

“Staying with Ford products and moving to the modular Ford gear. One of our highlights this year are our Coyote springs. They are capable of high lift, .600 lift, which is a good amount of lift and useful in many racing applications.”

“We have developed a stout spring for LS drag racing that is unique because at standard installed height it has 870 pounds open pressure … obviously a roller cam application. But to have that much pressure at the such an installed height is unique in the industry at this time. The advantage of this is you can have high lift, or high RPM, or both, and not have to contend with valve float. We’re talking about the 9,000- to 10,000-rpm range.”

“We have developed a stout spring for LS drag racing that is unique because at standard installed height it has 870 pounds open pressure … obviously a roller cam application. But to have that much pressure at the such an installed height is unique in the industry at this time. The advantage of this is you can have high lift, or high RPM, or both, and not have to contend with valve float. We’re talking about the 9,000- to 10,000-rpm range.”

Tom Razzano, Sport Compact Applications

Manley’s east coast regional sales manager, Razzano is a Jersey Boy with a the classic combination attitude and street savvy. He’s an accomplished pitchman who had been in the trenches of high performance automotive sales for 13 years before joining the Manley ranks.

“We are introducing our stock static compression ratio EcoBoost 2.3-liter piston. Like our other pistons they’re forged from premium 2618 alloy and we maximize all the radii and wall thicknesses to create a piston that can take all the power that we feel this platform can make. The one thing we retained from the OE is the shape and size of the direct injection trough because we felt the engineering capabilities of Ford are pretty substantial and they know how best to redirect the flow of the high-speed fuel. Other than that we follow our manufacturing protocols to make the finest pistons in this country.”

“We are introducing our stock static compression ratio EcoBoost 2.3-liter piston. Like our other pistons they’re forged from premium 2618 alloy and we maximize all the radii and wall thicknesses to create a piston that can take all the power that we feel this platform can make. The one thing we retained from the OE is the shape and size of the direct injection trough because we felt the engineering capabilities of Ford are pretty substantial and they know how best to redirect the flow of the high-speed fuel. Other than that we follow our manufacturing protocols to make the finest pistons in this country.”

“We have also developed a Turbo Tuff connecting rod which we currently manufacture for the 2.0-liter and the 2.3-liter EcoBoost. Like all of our Sport compact Turbo Tuff line they are the most asked for and best connecting rod in the field. We have many years of development in making these rods withstand huge amounts of horsepower. We’ve taken all the experience we’ve attained from Subaru, Mitsubishi, Honda, Toyota, and Nissan and wrapped it up into this new Ford application and are confident it can handle all the power Ford enthusiasts can throw at it.”

“We have also developed a Turbo Tuff connecting rod which we currently manufacture for the 2.0-liter and the 2.3-liter EcoBoost. Like all of our Sport compact Turbo Tuff line they are the most asked for and best connecting rod in the field. We have many years of development in making these rods withstand huge amounts of horsepower. We’ve taken all the experience we’ve attained from Subaru, Mitsubishi, Honda, Toyota, and Nissan and wrapped it up into this new Ford application and are confident it can handle all the power Ford enthusiasts can throw at it.”

“This is our H-Tuff line of H-beam rods. We made the Subaru version a few years ago and it has been wildly successful … it’s just an upgraded H-beam design connecting rod. We are now adding to this line with applications for Mitsubishi Evo VIII and IX, Eclipse, and Evo X, Toyota 2JZ, and Mazdaspeed engines. These rods are a bit heavier because we have put more wall thickness in the blades to enhance strength making an extremely capable rod and value based H-beam price.”

“This is our H-Tuff line of H-beam rods. We made the Subaru version a few years ago and it has been wildly successful … it’s just an upgraded H-beam design connecting rod. We are now adding to this line with applications for Mitsubishi Evo VIII and IX, Eclipse, and Evo X, Toyota 2JZ, and Mazdaspeed engines. These rods are a bit heavier because we have put more wall thickness in the blades to enhance strength making an extremely capable rod and value based H-beam price.”

So who won this ‘heated’ exchange? Mr. Mecklenburg from the Golden State, Mr. Razanno from the Garden State … Mr. Trump? No, the clear winner here is any enthusiasts looking to make serious, reliable horsepower.