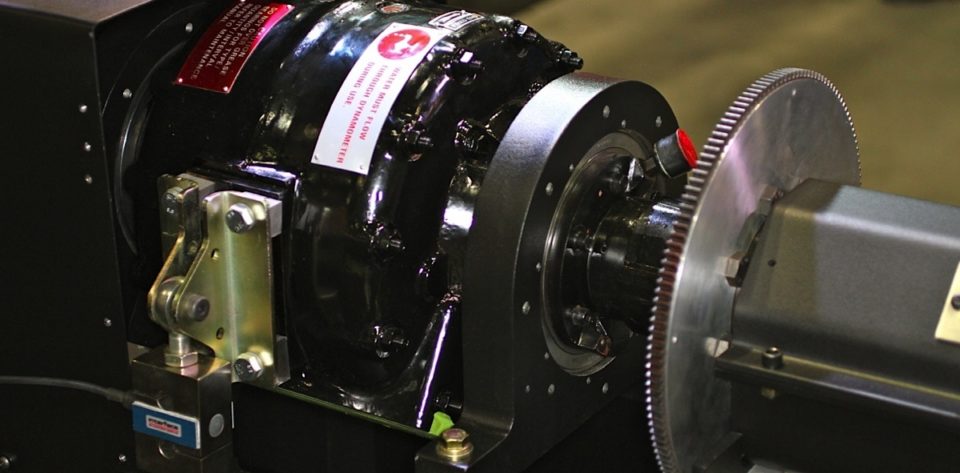

Superflow’s most powerful dyno now has standardized features that clean up the dyno room and allow for easier installation and operation.

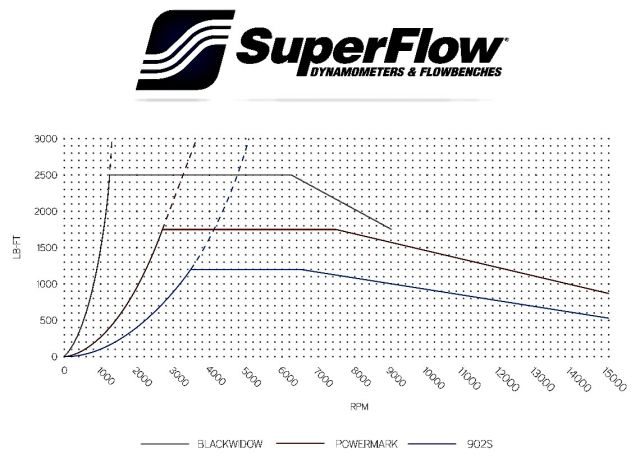

The SF-Black Widow is rated up to 11,000 rpm and 3,000 horsepower with a max of 2,500 lb-ft torque. That’s higher than the 2,500-horsepower capacity of the SF-Powermark and the 1,500-horsepower rating of the SF-902S.

“It can handle lots of torque at low speeds,” says Superflow’s Mark Giles. “That makes it desirable for the diesel and marine markets.”

Superflow introduced the Black Widow in 2010 with the units set up differently as the line grew.

“Now everything is more standardized,” says Giles. “Such as, the engine cart is now compatible with our other dynos. And we’ve added the boom to move all the hoses and wires out of the way.”

The integrated boom supports both the sensor box and cooling tower and features cable stays to route the transducer wires up and away from the engine. It also returns the engine water to the non-pressurized cooling tower that is located behind the boom and out of the way.

“Now you can actually get to the engine to change cams or check timing without hoses or tanks in your way,” says Giles.

The new sensor box includes four LCD displays to any channel from the WinDyn software. Other convenience features on the Black Widow include a tool tray with cutouts, fully adjustable roll-around engine-docking cart and an integrated starter mount. The latter means that a flywheel, bellhousing and engine-mounted starter are not required.

Here's a comparison of the three SuperFlow dynos. Note the high torque loads that the Black Widow can support at low rpm.