ARP’s new Ultra-Torque assembly lubricant can eliminate the need to cycle fasteners before final assembly.

ARP’s new Ultra-Torque assembly lubricant can eliminate the need to cycle fasteners before final assembly.

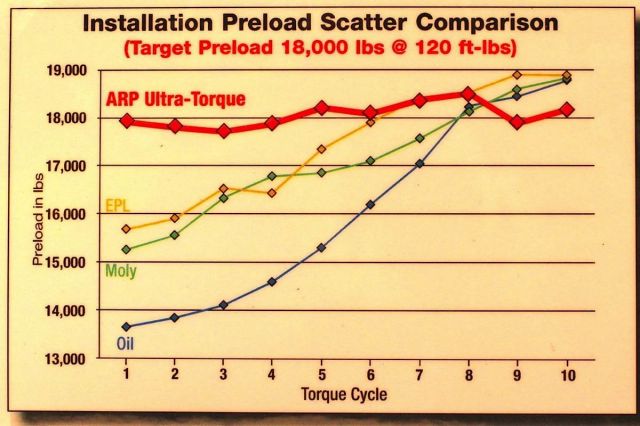

Critical fasteners such a main, head or rod bolt should always be lubricated when installed. A lubricant reduces the impact that friction has on the torque reading and the fastener’s ability to reach the required preload — especially in the first few tightening cycles. More specifically, a lubricant can reduce tension preload scatter, or the preload growth that a new fastener undergoes between the first and 10th cycles of fastening. Preload scatter usually doesn’t affect a fastener after the 10th cycle because the friction impact levels out and becomes repetitious for the remaining cycles. Different types of lubricants affect preload scatter. Measuring fastener stretch is the best way to confirm required preload, but that’s not always possible.

ARP tested different lubricants on a sophisticated torque-tension machine to develop a formula that minimizes preload scatter.

“There are times when you can’t use a stretch gauge, like in a diesel engine with offset rod caps,” explains ARP’s Chris Raschke. “Now the lubricant you use totally comes into play.”

ARP built a sophisticated torque-tension apparatus that provides consistent and repeatable tightening routines to evaluate different lubricants, such as engine oil or moly. ARP engineers then crunched all the data and contacted a lubricant supplier.

“We gave them the criteria for what we needed and they developed the formula,” says Raschke.

“We gave them the criteria for what we needed and they developed the formula,” says Raschke.

Ultra-Torque can give the engine builder between 95 and 100 percent of all ARP’s recommended installation preloads on the first pull without cycling the fasteners. It’s also designed to maintain within five percent of the installation preload on all remaining cycles, thereby ensuring consistent and repeatable housing and cylinder dimensions.

Other features of Ultra-Torque include 360-degree melting point, prevents rust and corrosion and prevents galling and seizing.

In an application where a fastener hole invades a water jacket, ARP recommends using its Thread Sealer on the threads to prevent leackage and Ultra Torque under the bolt or nut (with studs) shoulders to reduce friction.