The Evo X has done yeoman’s work taking the baton from the Evo IX and running with it. The X is built on a larger platform, which represents a paradigm shift in styling, going away from the Evo’s rally racing lineage, and features an all-new powertrain.

The Evo X has done yeoman’s work taking the baton from the Evo IX and running with it. The X is built on a larger platform, which represents a paradigm shift in styling, going away from the Evo’s rally racing lineage, and features an all-new powertrain.

The Mitsubishi Evo X is the only version to run the 2.0-liter turbocharged 4B11T engine, and like its predecessor, the 4G63, the boosted four-banger is a great candidate for power tuning. This particular Evo X GSR is the pride-and-joy of our shop technician turned staff writer, Kyle Kitchen. Kyle is not shy about the Evo ownership experience as he commutes and tracks the Mitsubishi on a semi-regular basis.

The Mitsubishi Evo X is the only version to run the 2.0-liter turbocharged 4B11T engine, and like its predecessor, the 4G63, the boosted four-banger is a great candidate for power tuning. This particular Evo X GSR is the pride-and-joy of our shop technician turned staff writer, Kyle Kitchen. Kyle is not shy about the Evo ownership experience as he commutes and tracks the Mitsubishi on a semi-regular basis.

Kyle has been on a horsepower quest for quite a while. He has already installed a host of aftermarket parts and we have chronicled some of his exploits here at Revved. We’ve covered the installation of a Moroso oil accumulator to keep oil pressure steady during high g-force turns on the track, as well as a Takeda exhaust to replace his homemade system and increase exhaust flow.

Laying The Foundation For Performance

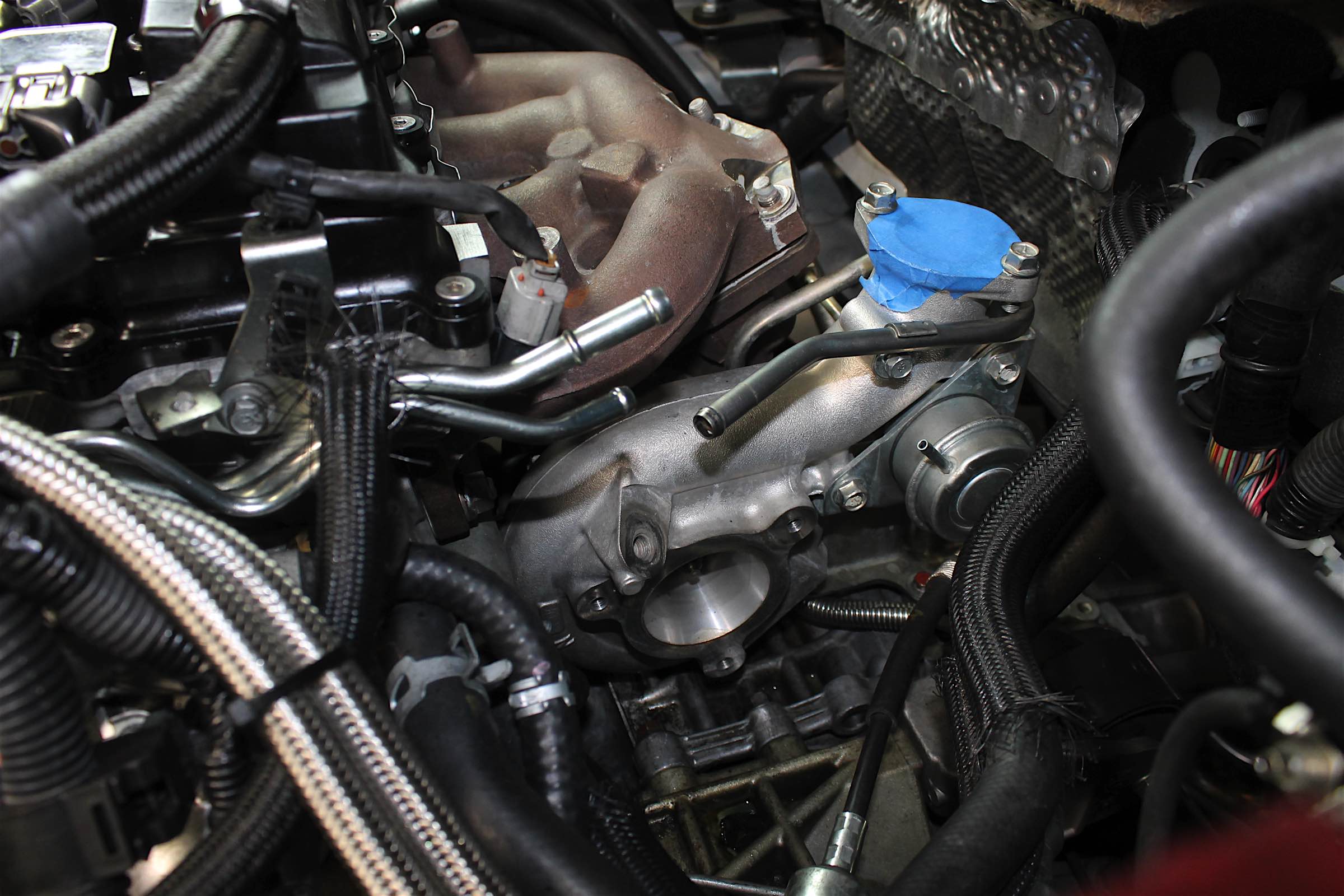

In late 2015, Kyle stepped up and set the stage for serious performance by dropping a fully built 4B in the engine bay of his Wicked White Evo. The block is home to custom JE pistons, Manley Turbo Tuff I-Beam rods, and ACL race series main and rod bearings. It’s topped with a MAP Stage 1 cylinder head that is secured with an ARP Pro-series head stud kit.

The head runs AMS TMP cams, GSC beehive valve springs, and GSC titanium retainers. A set of ASNU 1,150 cc injectors were tuned to run on sweet E85 corn juice. Power is sent through a Jack’s-built transmission.

One of the coolest aspects of Kyle’s build is the fact that he installs all of his own parts, tune’s the car himself, and is always learning more about the 4B11T engine and its potential. At this stage of the game his engine and driveline were built to the hilt, making it clear to see that the stock snail could never keep pace. A bigger turbo was needed.

Garrett GTX3076R

We reached out to Garrett for a turbo that could make the built engine hustle. We explained to Tim Coltey, Garrett’s marketing specialist on the aftermarket side, that we wanted a power curve that was wild enough for the track but tame enough to be streetable on the daily.

Coltey was quick to point to the GTX3076R. “Teamed with the 4B11 this turbo is a good fit with its billet wheel and ball-bearing technology,” says Coltey. “The 76 mm compressor wheel is good for up to 640 horsepower which is right in the sweet spot for the Mitsubishi’s 2.0-liter engine as well as the car’s intended usage.”

Coltey said the GTX3076 was chock full of innovation. “The unit’s forged, fully machined compressor wheel takes advantage of the latest aerodynamic technology, giving Evo owners better boost response.” He added that the wheel assembly contains dual ceramic ball bearings for improved balance and longevity and the turbo’s ported shroud compressor housing increases surge resistance. These benefits are key for a turbo that has an eye on the time attack circuit.

Fuel Injector Clinic 2,150 cc Injectors

To maximize the tuning potential of this combination, Fuel Injector Clinic recommended a set of its massive 2,150 cc injectors. Tim Jilg, Fuel Injector Clinic’s general manager, said that despite their big number, 2,150 cc injectors are a good fit for this build.

“Our 2,150 cc injectors are often a favorite choice for racecars as well as big power streetcars because they offer an incredibly high flow rate to support big horsepower numbers, all while maintaining smooth idle and good light-throttle behavior,” says Jilg. “We precisely match all of our injector sets by both flow rate and individual latency values and include that data in each box with our Data Match Technology sheet. These extra steps ensure that injectors fuel each cylinder equally and allows for easy, straightforward tuning, with great results.”

Jilg says the injectors are suitable for use with both gasoline and E85, so Kyle will have the option of using either type of fuel. He cautioned that the only thing to note is that these injectors are not compatible with fuels that have the additive MTBE in them.

He also indicated alcohol-based fuels like E85 are hygroscopic, meaning they absorb water, so it is important to take some preventative measures to avoid issues that can result from the water entering the system and leading to corrosion inside the injectors and other fuel system components.

“The best thing to do is to drive the car regularly to make sure there is always fresh fuel in the system,” says Jilg, “especially with an alcohol-based fuel like E85. If you are going to store the vehicle for a period of time we recommend storing it with gasoline in the tank. If you store your vehicle for a period of time with E85 in the tank, you’ll run the risk of the water in the E85 separating from the ethanol which can lead to corrosion.”

“The best thing to do is to drive the car regularly to make sure there is always fresh fuel in the system,” says Jilg, “especially with an alcohol-based fuel like E85. If you are going to store the vehicle for a period of time we recommend storing it with gasoline in the tank. If you store your vehicle for a period of time with E85 in the tank, you’ll run the risk of the water in the E85 separating from the ethanol which can lead to corrosion.”

Per Jilg, “If you ever remove the injectors, thereby exposing the fuel system to air, (and the water vapor it contains, we suggest you “pickle” the injectors by manually pulsing them while flushing them out and then lubricating them, and finally sealing them in an airtight container to keep the moisture out.”

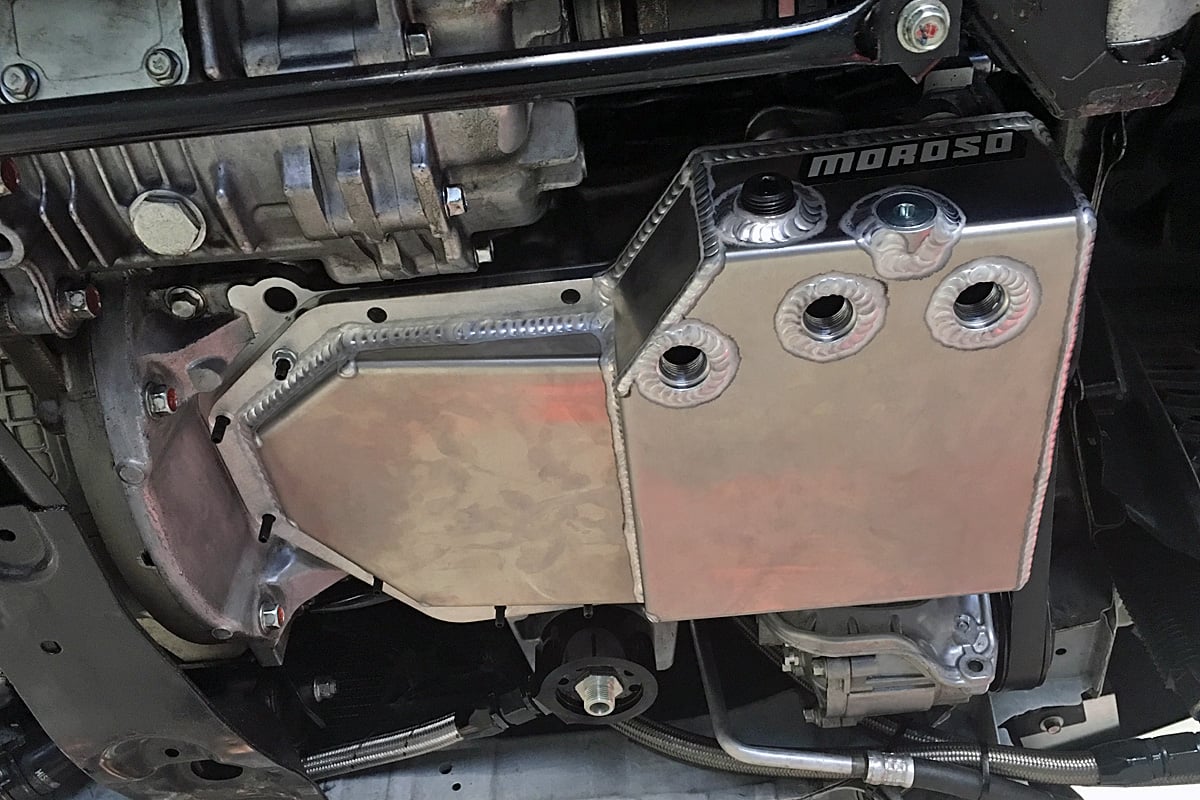

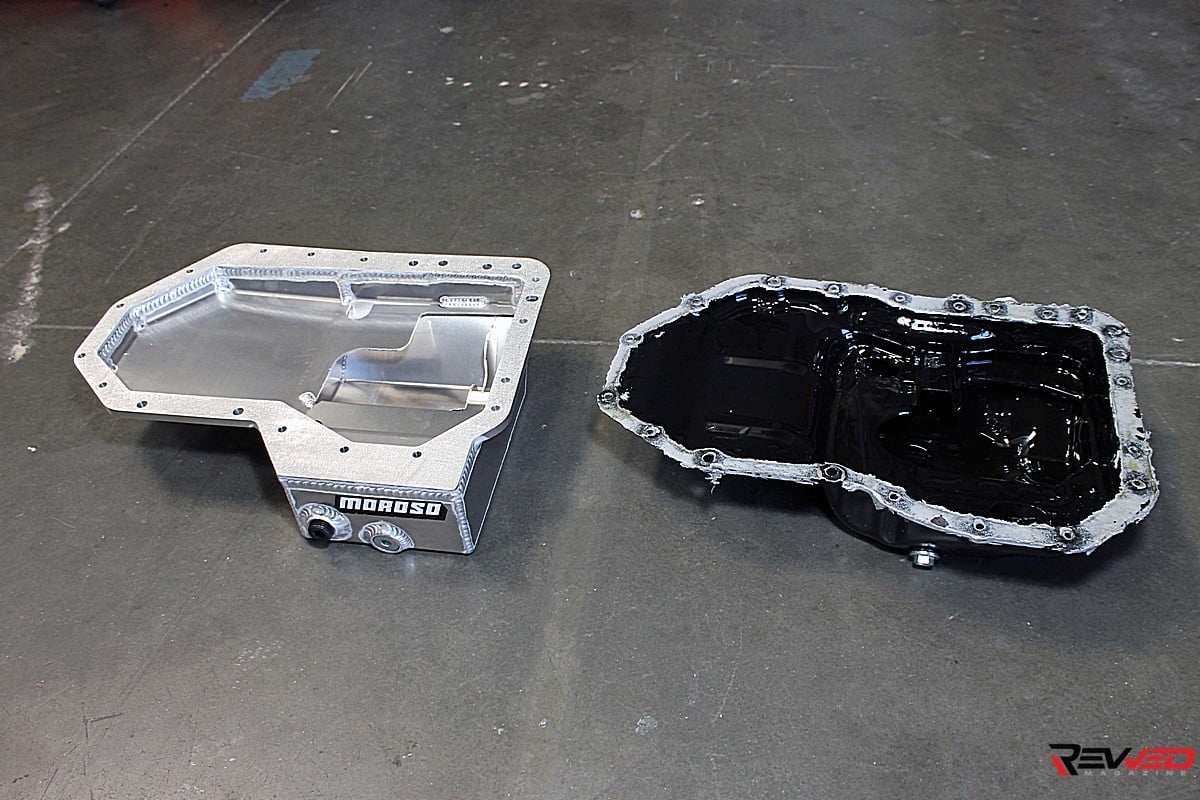

Moroso 4B11 Oil Pan

And as the Evo neared its jump-off point to bigger boost, Kyle noticed the 4B11’s factory oil pan had a pretty bad leak. He attempted to fix it numerous times between track weekends with little luck. With so much riding on the build, Moroso stepped up and sent us one of their Evo X oil pans.

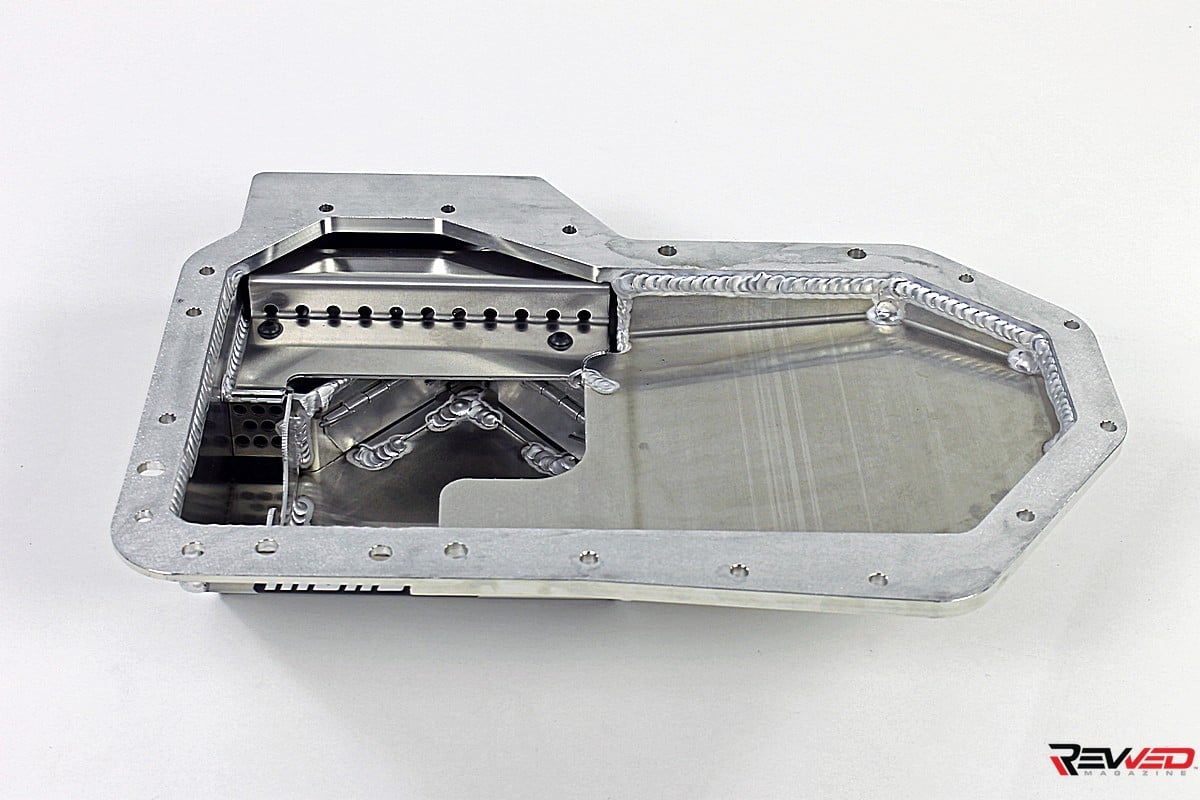

The oil pan is the perfect combination of race tech and street cred. Moroso’s Thor Schroeder offered insight into the research and development of the pan.

“On the race side we set off to engineer a race-proven baffling system in the Evo X,” he explained. “We got a full long-block with an OEM oil pan. We looked at the crank throw, what the aftermarket was doing for stroker cranks, how the engine is orientated in the car – including what angle the engine is at, took into consideration that the design of our oil pan would be optimal for road racing yet also be an excellent drag race oil pan with no comprises.”

“Also, we took in consideration that the pan would be installed on street cars that are track day weekend racers, which meant the oil pan had to fit on cars with factory air conditioning,” Schroder added. “After all of this information was gathered, an oil pan rail and a sheetmetal sump were designed and produced. Samples were sent out; for example to a NASA road racer who runs on full slicks and an enthusiast who regularly drag races his Evo. A common thread of these racers was their ability to datalog, and complaints of oil pressure problems. From the get-go our proto-pan took care of the oil pressure fluctuations that these two racers were seeing before using our oil pan. After proving that our basic configuration worked, we finalized the design and released the oil pan to the public.”

With a larger turbo providing the boost, the flow characteristics of the entire turbo system have gone up a notch or two. One of the areas that needed to be addressed was blow-off valve (BOV) performance. We knew Turbosmart had many vehicle-specific valves, and sure enough it had a Type 5 Dual-Port for the 4B11.

Turbosmart Blow-Off Valve

We asked Turbosmart’s Marty Staggs how superior blow-off valve performance translates into the real world. “More air requires more flow from the BPV/BOV,” he explained. “The factory bypass valve (BPV) is designed to only flow as much air as is required from the factory turbo. When you upgrade the turbo and/or increase the boost significantly over stock, the factory BPV becomes inadequate and can cause turbo-damaging compressor surge. With a proper blow-off valve, the turbo will ‘free-wheel’ during shifts allowing the shaft speed to stay up, which reduces the boost recovery time, or dreaded turbo lag. This provides better lap times and a more satisfying driving experience.”

We asked Turbosmart’s Marty Staggs how superior blow-off valve performance translates into the real world. “More air requires more flow from the BPV/BOV,” he explained. “The factory bypass valve (BPV) is designed to only flow as much air as is required from the factory turbo. When you upgrade the turbo and/or increase the boost significantly over stock, the factory BPV becomes inadequate and can cause turbo-damaging compressor surge. With a proper blow-off valve, the turbo will ‘free-wheel’ during shifts allowing the shaft speed to stay up, which reduces the boost recovery time, or dreaded turbo lag. This provides better lap times and a more satisfying driving experience.”

Installing The Goods

Before we installed the Garrett GTX3076 turbocharger, we wanted to take care of our leaky factory oil pan and swap in that sweet Moroso pan. To start the process we drained the oil out of the engine so it wouldn’t dump all over us while taking the pan off. After removing the bolts, the pan popped right off, and we then proceeded to remove the felt gasket and excess silicone gasket material around the edge of the block.

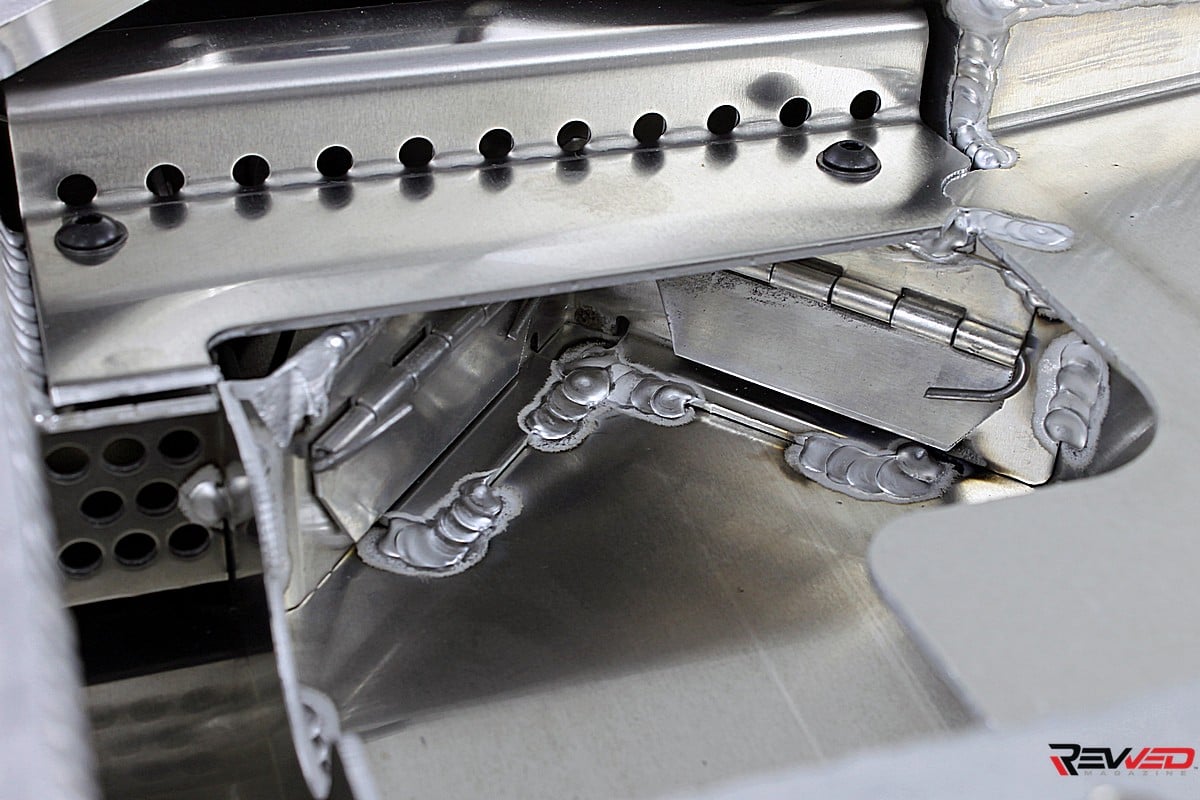

To remove all the gasket material, we used a razor blade and a green Scotchbrite pad. Once the surface was completely free of gasket material, we installed the studs that Moroso included with the pan. The studs are needed because the pan rail is significantly thicker than the factory pan rail, rendering the factory hardware useless.

With the studs in, fresh silicone gasket material was applied and smeared to cover the whole pan rail to ensure a tight seal. After that, we fit the pan over the studs, and started securing the pan with the supplied nuts, removing the excess gasket material that oozed out while tightening the fasteners.

You’ll notice that there are three plugs missing on the bottom of the pan; those are to access the last three nuts that need to be secured. Once they were secured, we popped the plugs back in, and the pan was good to go.

Next up on our to-do list was the Garrett GTX3076R turbocharger; the last piece to Kyle’s boost puzzle. As Kyle already disconnected the negative battery cable, removed his front bumper, and the plastic undertrays beneath the car, we started the extraction of the factory turbocharger by removing the strut tower brace, and the AEM cold air intake that was previously installed. After the intake was out, we proceeded to remove the turbo inlet hose and the intercooler piping that runs across the top of the engine.

Since the Garrett unit is a stock frame replacement for the factory turbo, right down to the internal wastegate, the installation only required minor trimming of the passenger-side inner driveshaft boot heat shield to clear the high flow oil drain line, and the heat shield on top of the transfer case to make room for the large .94 A/R turbine housing.

Dyno Testing The New Set-up

With Kyle rubbing his hands together like a dastardly cartoon villain, it was time to see what the bigger Garrett turbo was actually capable of pumping out. Since he was also upgrading the injectors and intake, those had to be re-scaled before Kyle could even begin thinking about driving the Mitsu, so he was eager to get the hubs on Makspeed Racing & Development‘s Dynapack spinning.

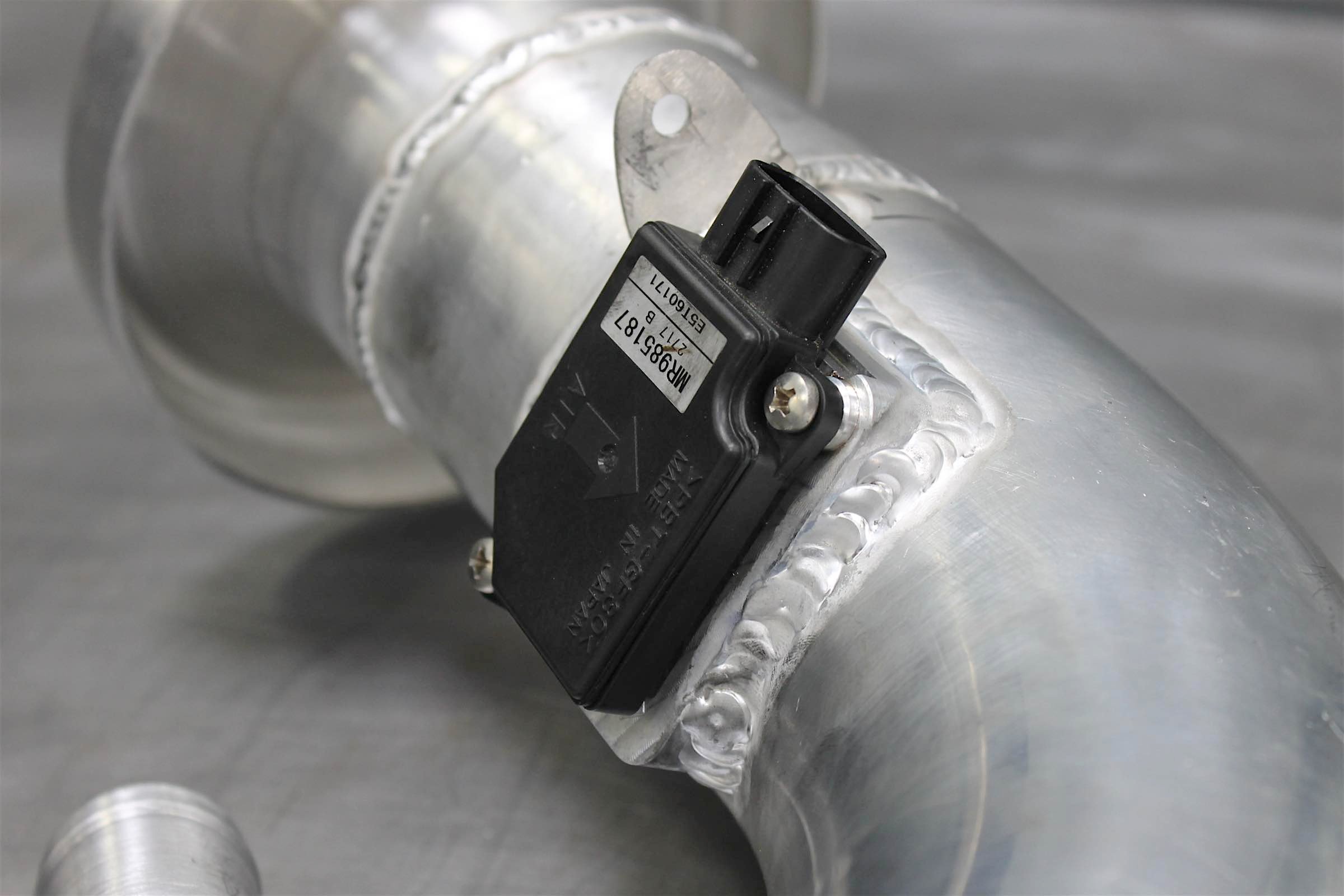

“In a scenario like this, it’s always easier to install and retune for the intake and injectors separately,” says Kyle. “It saves a lot of time if you’re rescaling a MAF sensor and are using properly scaled injectors and vice versa. If you tried to scale them both at the same time, it would be very difficult to do it accurately.”

“In a scenario like this, it’s always easier to install and retune for the intake and injectors separately,” says Kyle. “It saves a lot of time if you’re rescaling a MAF sensor and are using properly scaled injectors and vice versa. If you tried to scale them both at the same time, it would be very difficult to do it accurately.”

Kyle uses open source ECUFlash software to manipulate the maps and EvoScan to provide datalogging information. Kyle was quick to lay out the entire process.

“I chose to start with the 3.5-inch intake and rescale the MAF sensor, since I knew the 1,150 cc injectors I had in there were scaled 100-percent accurate,” he explained. “I started with the stock MAF scaling and measured the ID of the stock MAF tube (2.67 inches) and the new intake tube (3.38 inches). I then made some calculations and found I needed to increase the stock MAF scaling by 59-percent for my base map, which would run on the rich side in quite a few areas, but the car will actually start and will give you a much closer point to work from.”

“With a properly dialed in MAF, the 2,150 cc injectors were very simple to work in. Using the Data Match sheet provided by Fuel Injector Clinic, I was able to get the injectors really close to their final values, with just some fine tuning and adjustments to the low IPW (Injector Pulse Width) compensation table. We knew coming into this that these injectors were actually a little too big for my Evo, even on E85, so I have to idle a little on the rich side.”

Kyle continued, saying, “Once the intake and injectors were dialed in, I was able to actually start tuning for the Garrett turbo. Since this is a built motor that runs strictly on E85, I didn’t have to worry about limiting torque like stock-block Evo’s and could adjust timing by watching for MBT without much of a worry for knock.”

Kyle continued, saying, “Once the intake and injectors were dialed in, I was able to actually start tuning for the Garrett turbo. Since this is a built motor that runs strictly on E85, I didn’t have to worry about limiting torque like stock-block Evo’s and could adjust timing by watching for MBT without much of a worry for knock.”

MBT, or Maximum Brake Torque, is basically the optimal amount of ignition timing an engine can run at higher loads. The tuner finds the point where advancing the ignition timing no longer nets an increase in power and it plateaus. The first timing value that the plateau begins with would then identify MBT and would be the optimal ignition timing at that load. After finding MBT, it is usually advisable to pull two or three degrees of timing as a safety net.

“I use an electronic boost controller, which really makes wastegate adjustments very simple. The built motor was given to me by a close friend, and when he built the motor he chose not to have it sleeved for whatever reason. So, to limit power and keep cylinder pressure down, I set my boost target for a modest peak of 28 psi with the turbo tapering to 24 psi at redline,” Kyle concluded.

And The Dyno Says…

The 4B11 responded impressively to Kyle’s commands as it generated huge improvements. Previously, the Evo X’s built 2.0-liter stock TD05H-152G6-12T turbo maxed out at 26 psi peak boost and tapered to 18 psi at 7,000 rpm. This combo peaked at 4,791 rpm where 401 wheel-horsepower was generated. The typical tapering behavior of Evos, IXs and Xs, tend to produce peak numbers earlier in the rev range the one would usually expect. This is done to provide good early power and quick spool-up. Peak torque checks in at 473 lb-ft of torque at 4,198 rpm, thanks to the built bottom end.

With the big snail up and running, the 4B11 reacted as expected and took longer to spool, making about 50 horsepower less at 4,000 rpm. But paying off big-time in the engine’s sweet spot with the maximum gains being realized at 6,870 rpm, where the Mitsubishi belted out an additional 188 wheel-horsepower over the stock turbo.

With the big snail up and running, the 4B11 reacted as expected and took longer to spool, making about 50 horsepower less at 4,000 rpm. But paying off big-time in the engine’s sweet spot with the maximum gains being realized at 6,870 rpm, where the Mitsubishi belted out an additional 188 wheel-horsepower over the stock turbo.

Peak power hit at 6,895 rpm, as the engine pumped out an impressive 538 wheel-horsepower. The frustrating up-range power trail-off is now history as the GTX3076R keeps pumping to the end of the pull at 7,772 rpm, making more than 525 wheel-horsepower all the way to the end of the pull.

Kyle is quick to point out that with the car seeing more track time than street miles these days, he wasn’t looking to pull every bit of power out. “I wanted to focus on tuning the car for reliability with fairly modest power, in a way that would survive the high level of abuse a time-attack session puts on the engine, versus a street car that could get away with a more aggressive tune because the engine is not going to be spending extended periods of time at high loads and high rpm.”

Is this the Evo’s tune of a lifetime? If we know Kyle, there will be plenty of fine-tuning at the track. This tinkering will have little to do with peak numbers of 538 wheel-horsepower and 446 lb-ft of torque, but more with response under boost and smoothness of delivery. As with most enthusiasts, the build is never really over, and we will be keeping tabs on Kyle’s exploits.

Is this the Evo’s tune of a lifetime? If we know Kyle, there will be plenty of fine-tuning at the track. This tinkering will have little to do with peak numbers of 538 wheel-horsepower and 446 lb-ft of torque, but more with response under boost and smoothness of delivery. As with most enthusiasts, the build is never really over, and we will be keeping tabs on Kyle’s exploits.