Historically, the 2JZ engine is known as one of the most iconic engines in Japanese motorsports. Specifically, the 2JZ-GTE variant was developed for use in the most popular Toyota 2-seater sports car: the fourth-generation, or MKIV (mark-four), 1993 to 1998 Toyota Supra RZ and Supra Turbo. Standard with a cast-iron engine block, the 2Jz featured a closed-deck to remove any chance of cylinder movement, as well as dished piston tops for reduced compression. It wasn’t long before this engine’s true potential was discovered, with teams around the world winning races and breaking horsepower records. But, as found in this video from SXSBlog (sxsblog.com), all engines have their limits.

Exploring the Limit of the 2JZ

Rick Caston and his team have been hard at work building a 2JZ-GTE for their dirt-drag Polaris RZR with one goal: 1000 horsepower. Their build consists of forged rods and pistons, coupled with upgraded valvetrain and camshafts in the cylinder head. With a big turbo installed, Don, the builder and officially titled “Engine Calibration Editor”, cranked the boost to 30psi and managed 908 horsepower out of the small 3.0-liter engine. Satisfied with the result, Caston and the boys decided to hit the drag strip.

Unfortunately, things didn’t go so well.

A visual story-telling of complete engine failure

On the first pass the 900hp RZR launched hard and heavy off the line, ripping the front wheels off the ground. Being impressed with the power, Don said they had thrown “30 pounds of boost at it and it loved it,” and decided to make another pass. During the second run, “everything went from all thumbs up to everything screwed in about 1.4 seconds.”

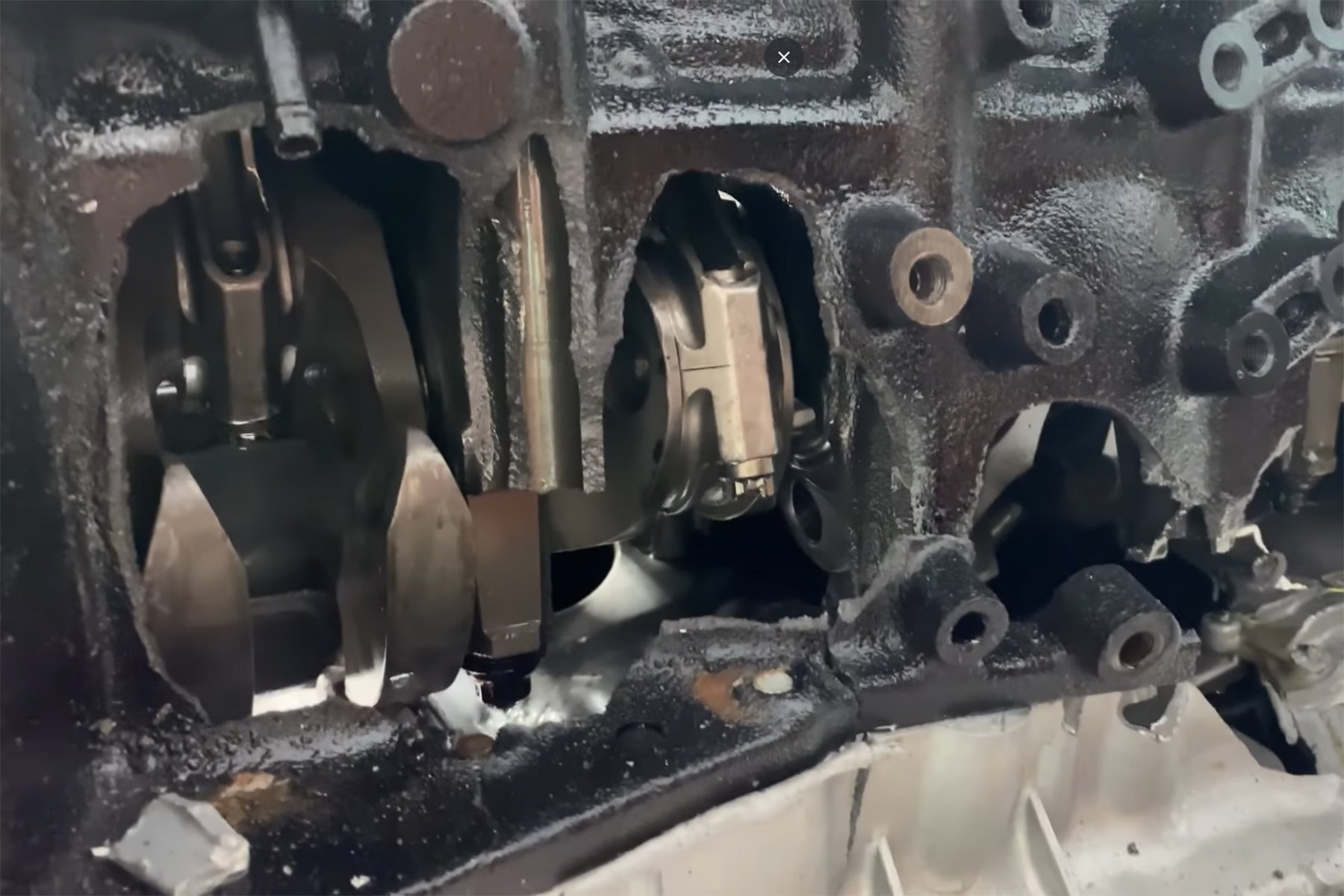

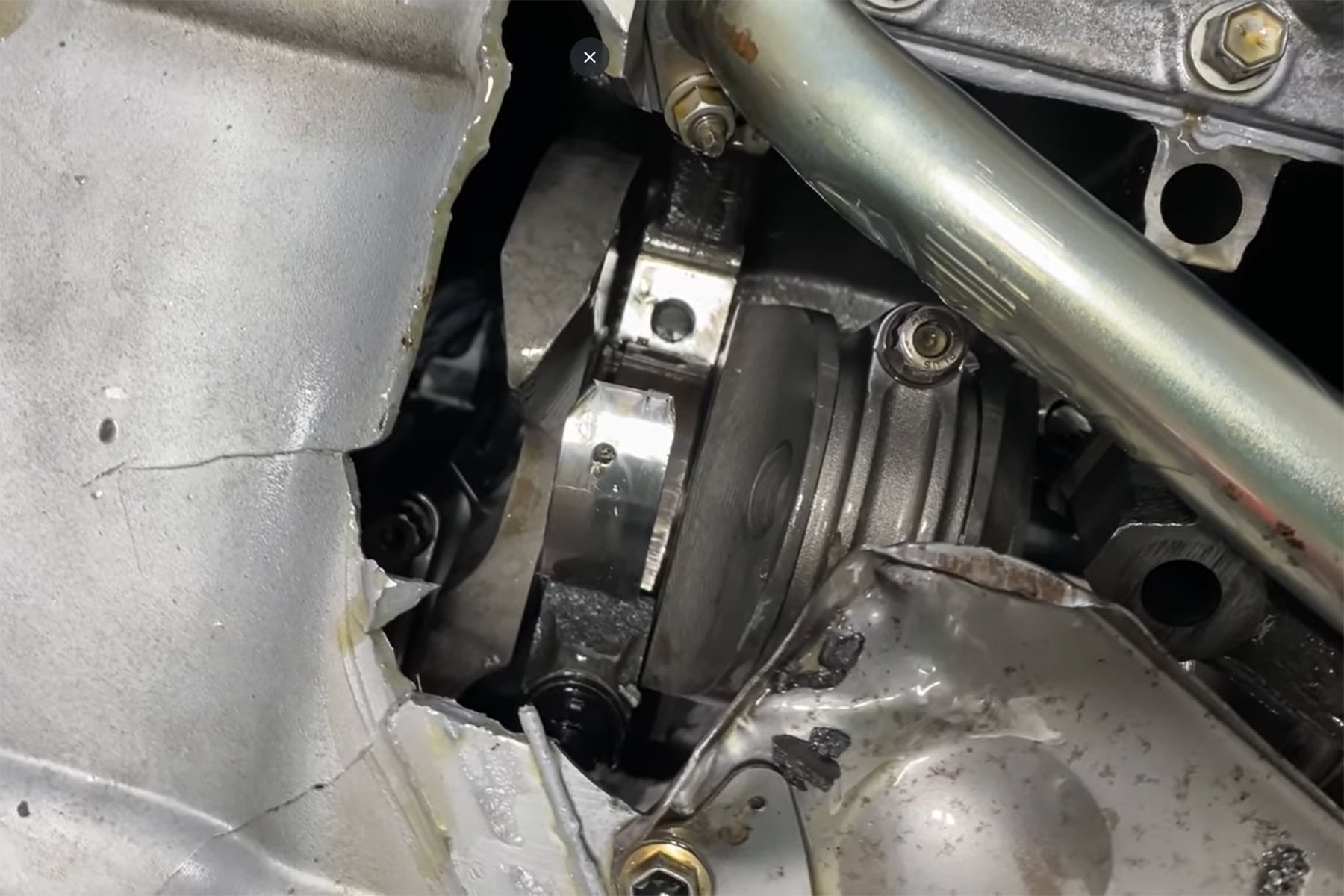

The engine suffered a catastrophic crankshaft main cap failure.

Reflecting, Don stated there was a momentary oil pressure loss during the first run: the first indicator of the main cap failure. Upgrading everything internally, the decision was made against upgrading the stock main caps to billet versions. This ultimately led to the explosive finale of this powerful build.

In the end, this is a tough lesson in Engine Building 101: Always fix the weakest link.