Diesel engines have their place among many facets of internal combustion enthusiast groups. While the majority of diesel applications are focused on industrial equipment, trucks that haul our food and vehicles that help us work there are more specialty niche markets many of us diesel enthusiasts don’t pay much attention.

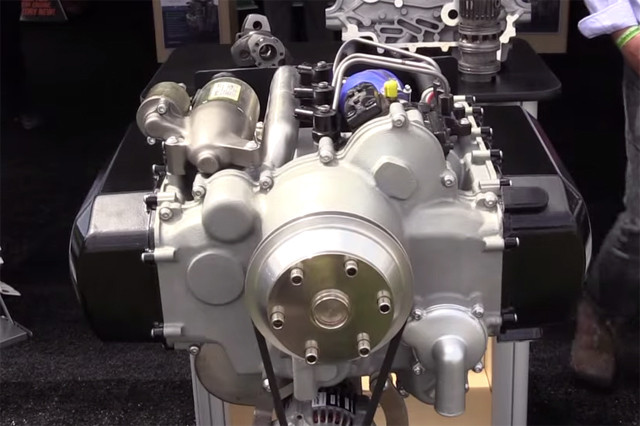

Aircraft are a rare application for our sturdy diesel power plants, but they are gaining momentum. The Gemini Diesel engine from Superior Air Parts fills a gap in this expanding market by offering a compact and clever solution to the problems of private pilots who wish to fly into remote locations where AvGas is scarce.

The Gemini engine may only produce 100 hp but in the world of light sport aircraft (LSA) that is plenty to propel a single private pilot into the skies for leisure and personal enjoyment. The priorities for engines in aviation communities are much different from those in the truck markets. In order of priority aviation engines must be reliable, light weight, compact, and efficient.

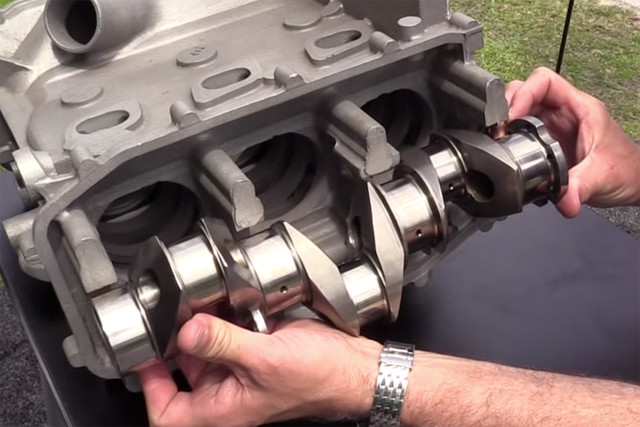

With its three-cylinder, six-piston, two-stroke design the Gemini Diesel takes technology from the German Junkers Jumo engines from the 1930s. The Junkers engines differ in that they applied their opposed piston design in a vertical plane, and produced far more power due to their massive displacement (nearly 17-liters).

More in keeping with todays propeller driven aircraft use, the Gemini is horizontally opposed for minimized frontal area, and displaces a much more modest volume.

The real advantage to the diesel engine in aircraft is fuel availability. 100LL (low-lead) is the standard fuel for light aircraft, it is formulated specially for aviation applications to accommodate problems such as vapor lock, and to prevent detonation in air-cooled engines under heavy loads.

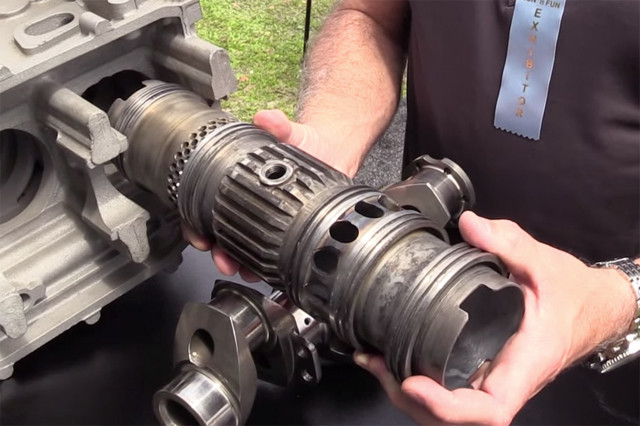

That’s not a valve cover! This two-stroke features sleeved cylinders to intake and exhaust it’s supercharged fuel air mixture.

As is well known to the diesel enthusiast these engines are not limited to a single fuel source. Commercial diesel fuel, bio-diesel, and Jet-A are acceptable sources to fuel this engine allowing the reach of the aircraft to extend into remote locations where AvGas may be unavailable.

The decision to produce a two-stroke diesel for aviation use has several points in its favor when considering the needs of the pilot. The fundamental lack of a valve train in two-stroke engine design greatly reduces the number of moving parts subject to wear and failure. Simplicity is a cornerstone of reliability in light aircraft engines.

Scott Hayes of Superior Air Parts shows us the cylinder sleeve for one of the three cylinders in the Gemini engine. The small intake ports can be seen on the left and the large exhaust ports on the right.

The requirement to include forced induction in the form of a supercharger or turbocharger is not bandaid to the two-stroke. While forced induction is common on aircraft engines it fills a different void than its application on the ground.

As an aircraft increases in altitude the air fuel mixture enriches, the addition of forced induction limits the losses in power as a result of the otherwise rich condition generated at altitude.

Superior Air Parts has given us a look into the exotic side of aircraft engines, not somewhere diesel technology usually leads us. For that I commend them, we look forward to their upcoming turbocharged 120 hp powerplant!

The Gemini Diesel is a horizontally opposed three-cylinder, six-piston, two-stroke engine for light sport aircraft.