You may be asking yourself: “Why would I need to check the clearance between my pistons and my valves, if everything I’ve purchased is specifically for a Mustang?” That’s a great question, as Late Model Restoration is here to answer that for us.

To keep things short and simple: when you’re building an engine, you’ll want to measure the clearance between the pistons and the valves on both the intake and exhaust sides to prevent any damage from occurring. If the clearance is inadequate the meeting between the piston and a valve of valves won’t be a friendly one.

This should be something that an engine builder or shop doing your engine assembly checks for you. However, if you’re like us and like to do your own wrenching at home, maybe topping off your short block, or upgrading your Fox body or SN95, knowing how to do this properly will not only save you a lot of headaches and heartache, but potentially some money as well.

In the video above, Landan Durham with LMR explains that piston-to-valve clearance is of course the distance between valve and the piston at top dead center (TDC). There are a few methods you can use to measure that distance, both of which are shown by Landan in the video.

In the video above, Landan Durham with LMR explains that piston-to-valve clearance is of course the distance between valve and the piston at top dead center (TDC). There are a few methods you can use to measure that distance, both of which are shown by Landan in the video.

Landan recommends that your piston-to-valve clearance should be around 0.120-inch for a street application – a number we’d also agree with as shown here.

He also explains that if you’re going to check your clearance, that you’ll need access to the following:

- Engine block

- Cylinder head

- Head gasket

- Roller rockers

- Push rods

- Dog bone or lifter retainer

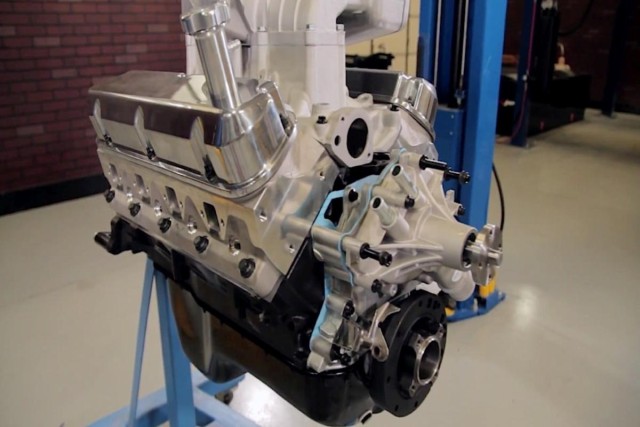

Pictured here are some of the items in the list above you'll need to measure your piston-to-valve clearance.

Like Landan explained, we also recommend the use of a dial indicator, as this will ensure accuracy when building your 302/351. If you’re interested in doing this for yourself, LMR actually has a ’85-’95 piston-to-valve tool checking kit available for your convenience on its website. Check out the kit here if you’re interested in purchasing it for yourself.