So, just how innovative, or crazy, is the idea of four pistons on a single connecting rod?

This dazzling video pops up on the web every few months in automotive forums or on Facebook pages, and while it fascinates mechanically minded viewers and mystifies others, not many know its true origins.

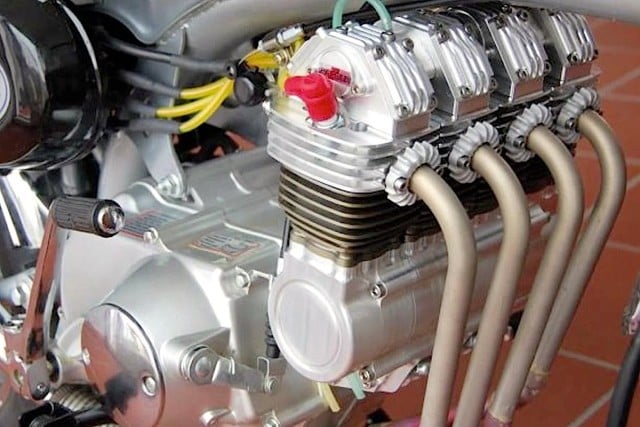

Hartmann-Wirthwein’s patented rotating assembly was first tested in this Honda-based 4-cylinder, which was installed in a mini-bike and is in running condition.

The patented crank-and-rod assembly is from the rather ingenious mind of Dieter Hartmann-Wirthwein, a German engineer who loves tinkering with small engines.

The idea was first put to the test in a 125cc 4-cylinder Honda-based configuration that Hartmann-Wirthwein installed in a Monkey Bike. Then adapted the principle to what originally was a 2-cylinder Ducati crankcase, which was then morphed into an 868cc V8 engine. He designed a new crankshaft to properly center the engine block in the bike’s frame, then built the remainder of the rotating and pivoting assembly along with the cylinders and valvetrain. Four carburetors mounted between the cylinder banks feed the cylinders.

Hartmann-Wirthwein named the engine Elenore, reportedly after the stylish Mustang in “Gone in 60 Seconds.”

And here’s the design in a V8 configuration. So far a running engine hasn’t been discovered in a video or on the web.

The arrangement appears to offer the same benefits as a flat-plane or 180-degree crankshaft in a conventional V8 engine–or think of it as two 4-cylinder engines coupled in a V formation at the crankcase. Either way, you get cylinders firing evenly between the banks, and the exhaust pulses are evenly charging out the headers to improve scavenging. Of course, the biggest disadvantage to a flat-plate crankshaft is the second-order vibrations. That’s usually not much of a concern in a racecar, but production cars have to address NVH issues. Not sure what this engine does in terms of vibration, but there has to be quite the balancing act between all the pivots and joints.

We know the engine in the mini-bike works, as there’s a video here, but the V8 doesn’t appear to have been prepped to run, yet. There are recent YouTube videos of Hartmann-Wirthwein testing a small 4-cylinder airplane engine, but we can’t tell if it’s utilizing a similar rotating assembly. Hope to see more innovations from this highly talented engine builder as well as an update on the V8.

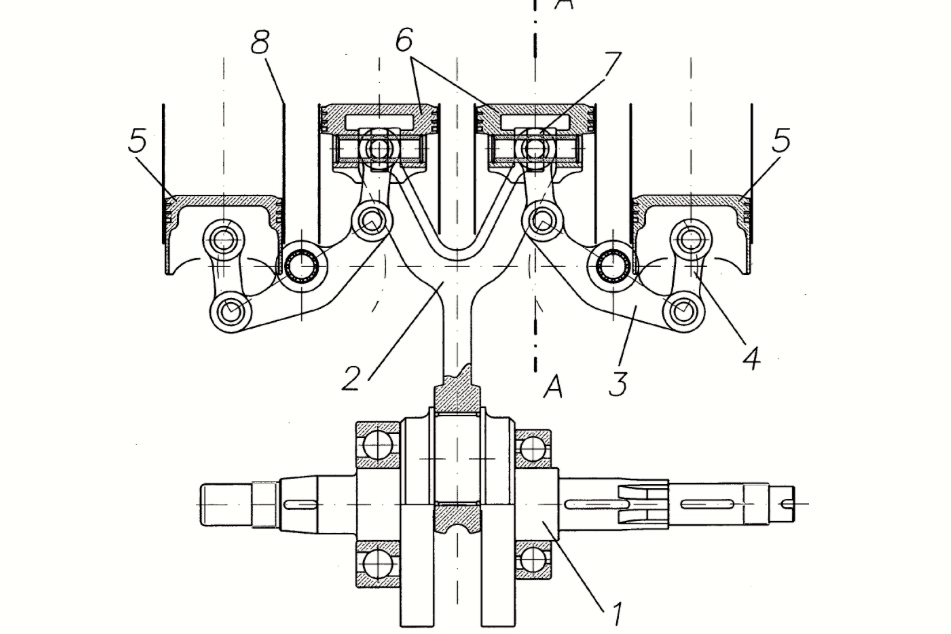

On the left is the original drawing for the patent applications. You can see some changes between the animation, especially in the mounting of the center pistons to the connecting rod. On the right is the V8 engine installed in a Ducati frame, but no exhaust is shown.