Porsche may be working on a variable-compression engine based on a recent patent application showing a connecting rod that changes its length with a hydraulic mechanism. According to news reports, the patent was sought in association with Hilite International, a global automotive engineering and consulting firm. That partnership filing indicates that the technology could be offered to other engine makers.

Porsche may be working on a variable-compression engine based on a recent patent application showing a connecting rod that changes its length with a hydraulic mechanism. According to news reports, the patent was sought in association with Hilite International, a global automotive engineering and consulting firm. That partnership filing indicates that the technology could be offered to other engine makers.

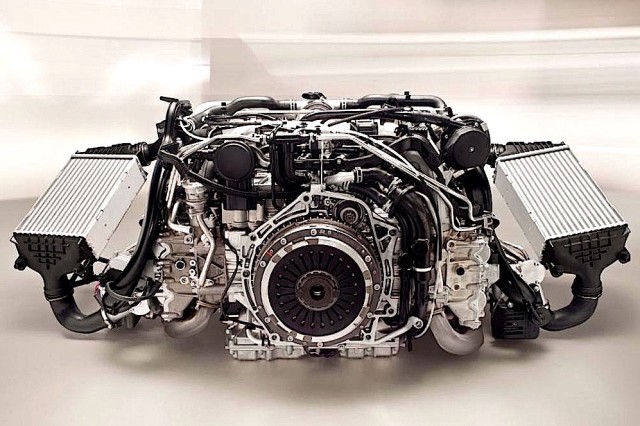

A variable-compression connecting rod could be useful in a high-performance turbo application like the Porsche 997 engine.

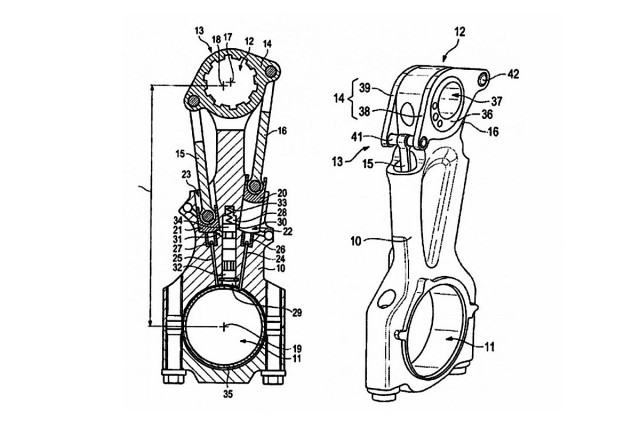

Basically, the concept is to adjust the center-to-center distance of the connecting rod as needed during the engine operation. A longer rod length increases the compression ratio of the engine because the piston will squeeze up higher into the combustion chamber. Variable compression would be a most useful tool on a boosted engine. Fuel consumption could be reduced while offering good power by running a high compression ratio during low loads. Engine response would also be improved in this scenario as turbo lag would be holding back power potential. When boost is needed and cylinder pressures increase, the compression ratio could be lowered to reduce the chance of detonation. Variable compression could also be useful in flex-fuel engines, running a high compression with E85 and lower compression with gasoline.

Variable compression is not a new concept. Saab experimented with a movable cylinder head (see video above) that increased or decreased the cylinder volume to change the compression ratio. Lotus once showed off a 2-stroke HCCI concept that used a movable puck in the cylinder head to increase or decrease the combustion-chamber volume.

The Porsche design looks similar to a FEV system (see video below) shown at the recent SAE conference. Both use hydraulic controls and an eccentric to change the rod length. No doubt exhaustive testing and validation will be required before such a system will be offered, but it’s an interesting idea that follows the current trend of increasing adjustability in an internal combustion engine. Just think how we already have adjustable cam timing and cylinder deactivation–all controlled with the engine’s lubrication system and a computer.